Paint can be abrasive for wet paint atomizers, such as gun and bell atomizers, leading to rapid wear of internal components.

Paints with large or hard pigments can wear down the internal components of atomizers. Metallic pigments, white pigments, and certain fillers are especially abrasive. For example, many white pigments, such as titanium dioxide (TiO2), zinc oxide (ZnO), and some historically used forms of lead white, have relatively high hardness.

Paint with a high solids content, which include more particles or thicker materials, can be more abrasive as they require more force to atomize.

Some additives in the paint, such as anti-settling agents or thickeners, can also contribute to abrasiveness by adding to the paint’s particle load.

Certain film-forming agents can harden within the atomizer, leading to abrasive effects on the internal surfaces.

Using high pressure or flow rates with abrasive paints can exacerbate wear and tear on atomizer components due to increased friction and impact.

Frequently inspect and clean the applicators to remove paint buildup and prevent excessive wear.

Choose applicators made from wear-resistant materials like carbide or ceramic to withstand abrasion and extend lifespan.

Adjust the paint’s viscosity to reduce friction and wear on the applicators, following manufacturer recommendations.

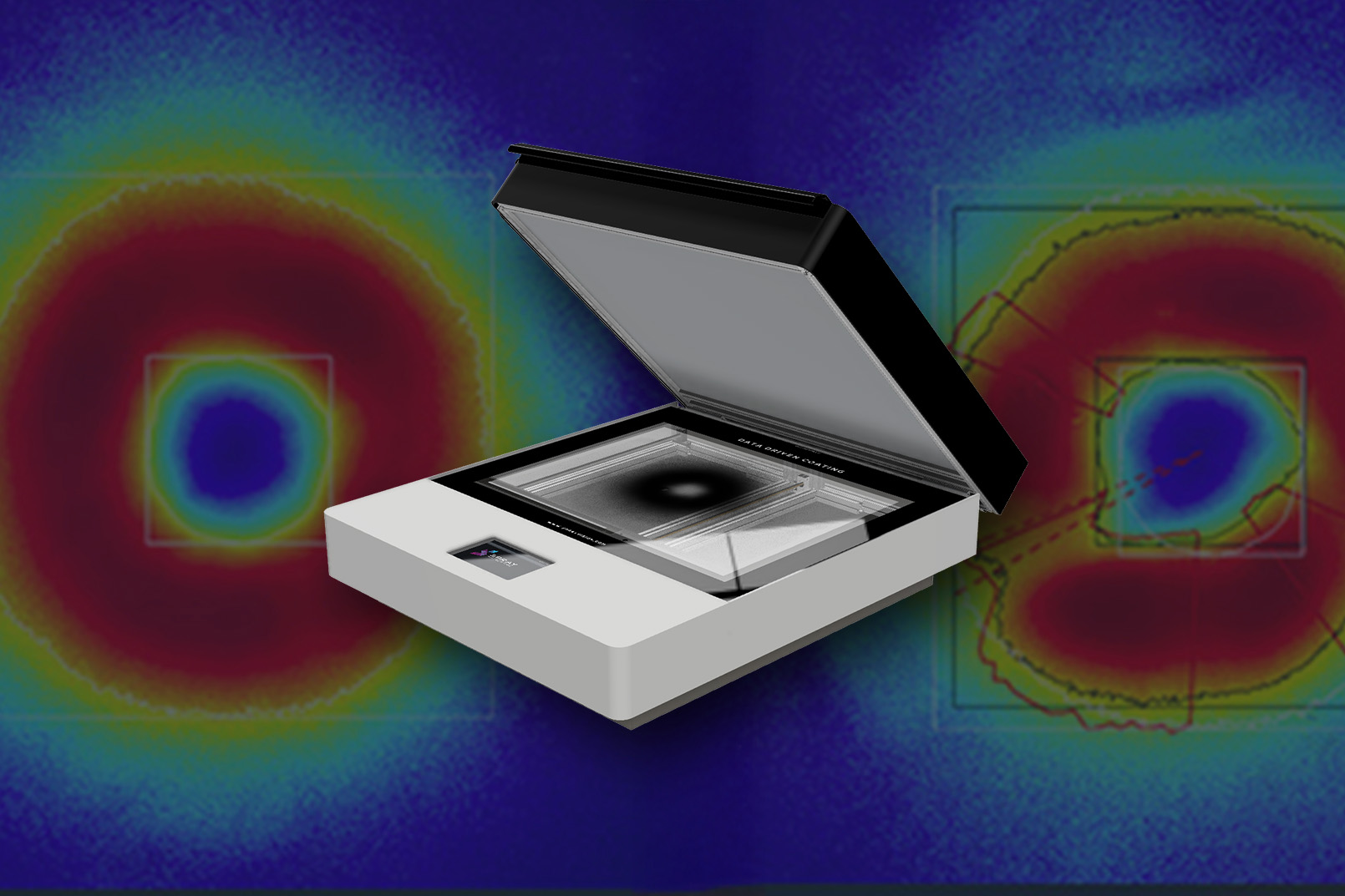

Use high-quality filters to remove abrasive particles from the paint, minimizing damage to internal components.

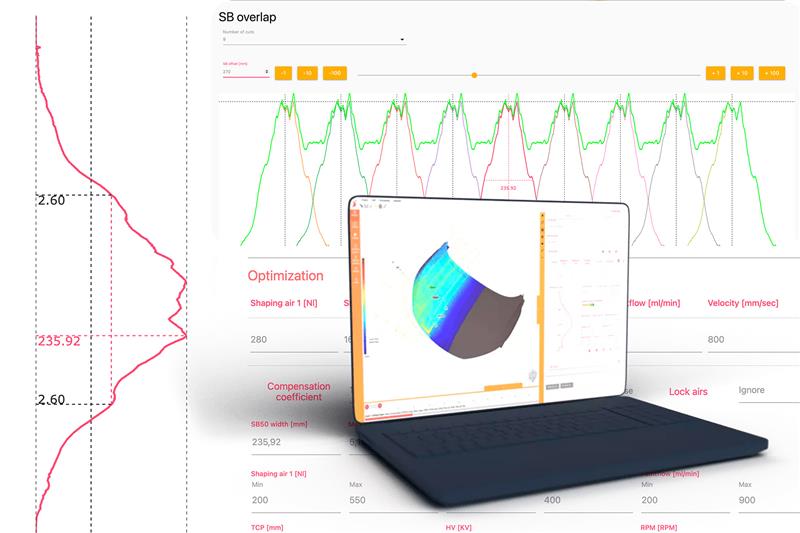

Fine-tune the air and fluid pressure settings to balance performance and reduce stress on the applicators.

Article by Jakub Kubíček, Application Technologist at SprayVision.

For more insights, follow us on LinkedIn.